Avoiding Misguided Pipeline Replacement Expenses

Date:

Publication:

Whichever the relevant adage — measure twice, cut once…a penny saved is a penny earned…look before you leap — the concept of being thoroughly prepared to minimize lost time, wasted money, or potential embarrassment is well founded. In water distribution infrastructure, performing condition assessments before replacing large swaths of piping can provide guidance on where to concentrate efforts and even the confidence to scale back from complete replacement to refurbishment and relining where warranted. Here are some guidelines on how utilities and their consulting engineers can leverage properly focused pipeline condition assessment and leak detection to be most cost effective, especially for smaller utilities with extremely limited capital budgets.

Evaluating Options ‘By The Numbers’

While many variables go into evaluating piping infrastructure conditions — i.e., pipe material, age, soil conditions, repair history, etc. — the cost of unearthing miles of piping buried under tons of earth makes it easy to understand why decision-makers might want to err on the side of caution. At $1 million to $2 million per mile for water pipeline replacement, it certainly makes sense to identify a more refined perspective of which piping segments really warrant wholesale replacement and which have 10 or 20 or more years of performance life left. That might mean reevaluating some of these traditional ‘rules of thumb’ to explore the tremendous influence condition assessment services can have on focusing capital expenditures to the areas where they are most needed:

- “Focus condition assessment on transmission pipes.” While it makes sense to assess the most mission-critical, high-profile backbone of a water network, there is a risk that focus on transmission pipes turns into “only assess transmission pipes.” The truth is that transmission pipes (typically defined as > 16” in diameter) usually represent only about 10 percent (by length) of most water distribution networks. Using more affordable non-invasive condition assessment technologies to evaluate the other 90 percent of the distribution system can help to identify the most cost-effective systemwide priorities for maintenance or replacement investments.

- “It is most efficient to replace water pipes at the same time as road resurfacing work is going on.” This concept can make sense in cases where municipalities can coordinate both activities…provided that the life expectancy of the water pipe is appreciably less than the life expectancy of the new road surface. A good condition assessment can help utilities determine areas where the remaining life expectancy of existing infrastructure would permit it to remain in service until the next scheduled road resurfacing project. That can lead to significant capital savings through targeted improvements as compared to the cost of wholesale replacement.

- “I already have a model to calculate which pipes have the highest risk of failure. Why would I need pipe condition data?” While refined models do help to categorize risk around known factors calculated from past experience, correlating additional insights from today’s conditions improves the confidence of those calculations. One utility was able to defer 60 percent of its planned replacement budget after supplementing its model with timely condition assessment data from just 20 percent of its network.

Identifying The Right Solutions

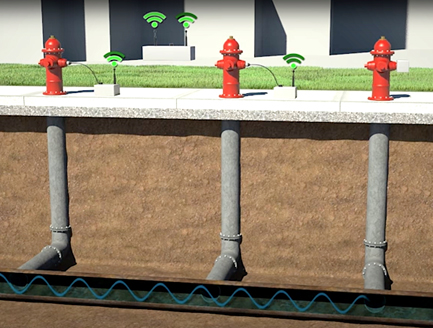

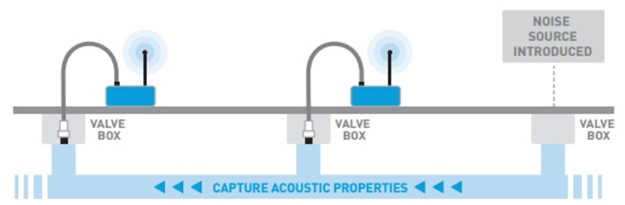

Condition-assessment technology for distribution lines falls into several categories — external non-invasive technologies (Figure 1), internal invasive technologies, and spot inspection technologies. Each offers different levels of capability based on cost, pipe material type, and the demands of the installation environment. The AWWA M77 Condition Assessment Of Water Mains manual offers both technical and practical guidance on how to approach condition assessment and on the various methods used to provide insight into the best use of pipeline replacement funding.

- Choose The Best Tools For The Job. Highly critical applications — such as water pipes feeding a nuclear plant — might require high-resolution electromagnetic scans to examine every inch of the pipeline. But non-invasive acoustic velocity testing can work very cost effectively to survey pipe segments in urban environments with lots of fittings and connections. Installations with plastic pipelines do not respond well to either technology, so those might need to be evaluated with leak detection technology instead of condition assessment technology.

- Compare Total Cost And Labor For the Value Returned. An important difference between invasive and non-invasive technologies is in the amount of prep work required to get a valuable data set and the amount of effort required to conduct the actual evaluation. Non-invasive condition assessment can provide leak detection as well as insights on pipeline conditions without having to redirect flows, dig a chamber, or insert a tool into water lines, so there is zero risk to pipelines or water quality (Figure 2).

- Support The Most Critical Real-World Needs. When less than 1 percent of infrastructure is replaced annually, it is important that expenditures are concentrated in the highest-risk areas. Years of acoustic velocity testing have shown that less than 10 percent of the pipeline length in cast iron piping networks typically represents more than 50 percent of structural failure risk. Finding those areas at a fraction of the cost of an invasive technology helps squeeze maximum value from minimal budgets.

- Expand The Functionality Of Condition Assessment. Condition assessment is not relegated strictly to making all-or-nothing pipe replacement decisions. It can also be used to guide decisions on whether to clean and line large segments of distribution piping instead of replacing them outright (Figure 3). It can even give utility engineers or consulting engineers another big-picture frame of reference on changing hydraulics relative to whether the utility’s customer base is growing or shrinking or where the utility is in its budget cycle.

Consider the experience of utilities that have changed their original plans based on the insights provided by cost-effective acoustic velocity testing. Those changes range from cutting capital costs for pipeline replacement by 50 percent in Edina, MN to ensuring worthwhile conditions for pipe relining in New Jersey to eliminating risky conditions for non-structural relining in Newark, DE.

Click here to read the article on Water Online